In the realm of flooring solutions, the choice often comes down to two standout contenders: polished concrete and epoxy flooring.

Each has its unique set of advantages tailored to different demands and aesthetics of a space. Delving into the nuances of polished concrete and epoxy flooring unveils a spectrum of features from durability to design versatility, setting the stage for an informed decision-making process. This exploration not only highlights the inherent qualities of each flooring type but also juxtaposes their costs, application methods, and optimal use cases.

Whether your priorities lie in the longevity, maintenance, or the visual appeal of your flooring, this comprehensive comparison serves as your guide to discerning which flooring solution—polished concrete or epoxy—aligns best with the specific requirements and aesthetic ambitions of your project.

What is polished concrete flooring?

Polished concrete flooring achieved by treating concrete slabs with chemical densifiers and grinding them down with progressively finer grinding tools. This process not only strengthens the surface but also imparts a glossy, reflective finish, transforming the concrete into an extremely durable, low-maintenance, and aesthetically pleasing floor.

Ideal for both residential and commercial settings, polished concrete offers a sleek, modern look while boasting an impressive lifespan and minimal upkeep requirements. Its versatility in finish and color options allows it to seamlessly integrate into various design schemes, making it a popular choice for those seeking a balance between functionality and style.

What is epoxy concrete flooring?

Epoxy flooring is a resilient and versatile protective coating applied over concrete floors, composed of epoxy resin and a hardening agent. Upon curing, it forms a smooth, durable surface that is highly resistant to wear, chemicals, and stains, making it an ideal choice for environments exposed to harsh conditions.

Epoxy floors are celebrated for their superior chemical resistance and the ability to incorporate slip resistant additives, enhancing safety in various settings. With a wide array of colours and patterns available, epoxy flooring can be customised to fit any design aesthetic, from industrial spaces to sophisticated spaces.

This makes it a favoured option for those looking to combine functional benefits with creative design in their flooring solution.

Why choose polished concrete?

Choosing polished concrete as a flooring option brings numerous benefits, notably its durability and longevity. This robust material withstands heavy foot traffic and industrial wear, making it a long-lasting choice for various settings.

Its low maintenance requirements—needing only occasional mopping—reduce long-term care costs and effort. Aesthetically, polished concrete offers a sleek and modern look, with customisable finishes that can mimic other materials or add unique visual interest to a space.

These characteristics make polished concrete an attractive, practical solution for those prioritising durability, ease of maintenance, and modern design in their flooring choices.

Durability and Longevity

Polished concrete is renowned for its durability and longevity, making it an excellent choice for flooring that needs to withstand heavy traffic and industrial wear. Its robust nature ensures that it retains its integrity and aesthetic appeal over the years, providing a durable solution for high-use areas.

Low Maintenance Requirements

A key advantage of polished concrete is its low maintenance requirements. Unlike other flooring options that require frequent waxing or sealing, polished concrete demands minimal upkeep—primarily routine cleaning. This simplicity in maintenance leads to considerable savings in time and money over the lifespan of the flooring.

Sleek and Modern Aesthetics

Polished concrete is not just about functionality; it also offers sleek and modern aesthetics. With its glossy finish and customisable options in terms of colours and patterns, it allows for extensive design flexibility. Whether the goal is a minimalist vibe or a distinctive decorative look, polished concrete can be tailored to match the specific design aspirations of any space.

Why choose epoxy flooring?

Opting for epoxy flooring brings a suite of benefits tailored for environments requiring robust, visually appealing surfaces. Its superior chemical resistance makes it an unparalleled choice for areas prone to spills and stains, maintaining its integrity against harsh substances.

The availability of anti-slip additives enhances safety, making epoxy flooring a go-to for spaces where slip resistance is paramount. Aesthetically, the wide variety of colors and patterns opens up endless possibilities for customisation, allowing for unique designs that can transform any space.

Additionally, the enhanced safety features and aesthetic versatility make epoxy flooring a compelling option for those looking to merge functional durability with creative design in their flooring solution.

Superior Chemical Resistance

Epoxy flooring stands out for its superior chemical resistance, an essential feature for spaces exposed to frequent chemical spills or harsh cleaning agents. This resistance ensures the flooring’s longevity and preserves its aesthetic appeal, protecting your investment in a high-quality flooring solution.

Wide Variety of Colours and Patterns

The wide variety of colours and patterns available with epoxy flooring allows for extensive customisation. Whether aiming to align with corporate branding or to achieve a specific design vision, epoxy offers the flexibility to create a unique and visually compelling environment, making it a versatile choice for any design palette.

Enhanced Safety with Anti-Slip Additives

Safety is enhanced in epoxy flooring through the integration of slip resistant surface additives, significantly reducing the risk of accidents in wet or high-traffic areas. This feature makes epoxy flooring a strategic choice for ensuring the safety and well-being of occupants, providing peace of mind in addition to aesthetic and functional benefits.

How do they compare in cost?

When comparing polished concrete and epoxy flooring in terms of cost, it’s essential to consider both the initial installation costs and the long-term maintenance costs.

Polished concrete often has a lower initial cost due to its simpler preparation and application process over existing concrete slabs. However, the price can vary depending on the level of grinding required and any custom finishes desired. On the other hand, epoxy flooring might present a higher upfront cost, particularly for extensive surface preparation or custom designs, but its durability and resistance to damage can lead to lower maintenance costs over time.

Ultimately, the choice between polished concrete and epoxy flooring should factor in not just the initial investment but also the anticipated maintenance expenses to determine the most cost-effective solution for a given project.

Initial Installation Costs

The initial installation costs for polished concrete tend to be lower, leveraging the existing concrete slab with a process that includes grinding and polishing to achieve the desired finish. This cost-effectiveness is due to the relatively straightforward preparation and application process.

Conversely, epoxy flooring often commands a higher initial investment. The comprehensive surface preparation—repairing, cleaning, and priming the concrete—alongside the cost of epoxy materials, contributes to its higher upfront cost.

Long-term Maintenance Costs

Regarding long-term maintenance costs, polished concrete emerges as the more economical option. Its robustness translates to minimal maintenance, significantly reducing the need for repairs or replacements over time.

Epoxy flooring, while also durable and resistant to various forms of damage, may necessitate reapplication or repairs, especially in environments with heavy traffic or significant chemical exposure. These potential maintenance requirements can increase the overall cost of epoxy flooring throughout its service life.

How do they compare in application processes?

The application processes for polished concrete and epoxy flooring differ significantly, impacting the project timeline and complexity. Polished concrete involves mechanically grinding and polishing the existing concrete surface, a process that can vary in duration based on the desired level of sheen and the condition of the concrete.

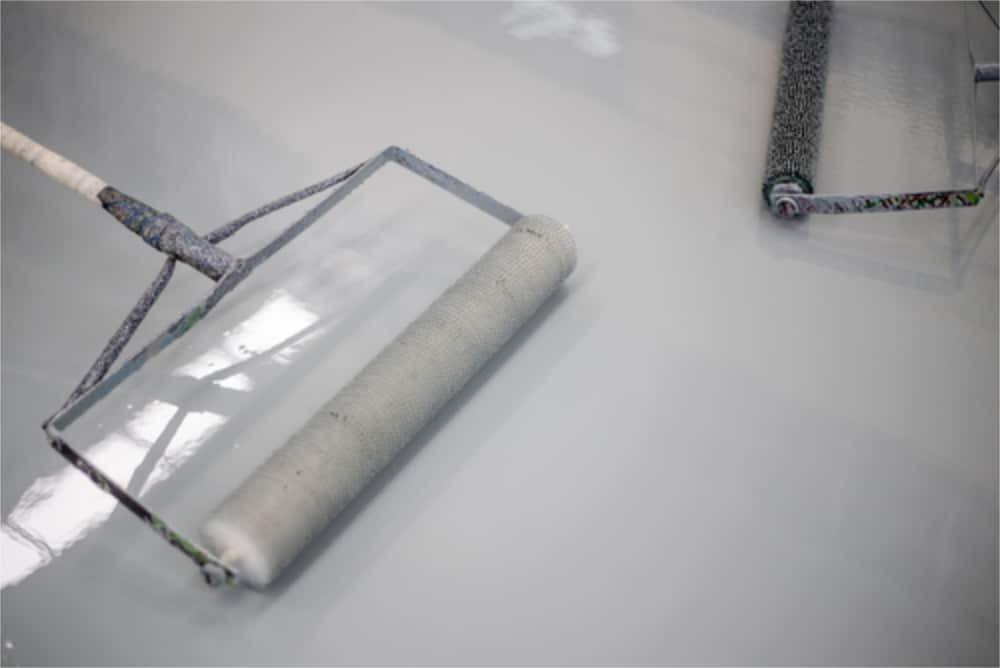

This method is generally straightforward but requires specialised equipment and expertise. In contrast, applying epoxy flooring involves a multi-step process that includes thorough surface preparation—cleaning, repairing, and priming the concrete—followed by mixing and applying the epoxy coating.

This process tends to be more labor-intensive and time-consuming, especially in ensuring the concrete is properly prepared to achieve optimal adhesion and finish. Each flooring solution has its unique application requirements, influencing the overall project timeline and the level of expertise needed to ensure a high-quality result.

Time Required for Installation

The time required for installation significantly differs between polished concrete and epoxy flooring. For polished concrete, the process can be relatively swift, with the duration largely dependent on the condition of the existing concrete and the level of gloss desired.

In most cases, this can be achieved within a few days. Conversely, epoxy flooring requires a more extended period due to comprehensive surface preparation steps and the necessary curing time for the epoxy, potentially extending the installation to a week or more, based on project size and specifics.

Complexity of Installation

When considering the complexity of installation, polished concrete is often seen as less intricate, needing specialised grinding machinery and knowledge but primarily working with the existing concrete surface.

Epoxy flooring, however, demands a detailed and labor-intensive preparation process, including moisture mitigation and surface levelling, to ensure the epoxy adheres correctly and lasts.

This level of preparation and attention to detail elevates the complexity of epoxy flooring installation, usually requiring the skills of experienced professionals to ensure a high-quality finish.

What are the best use cases for polished concrete floors?

Polished concrete excels in environments that require both durability and aesthetic appeal. Its robustness is unparalleled for high-traffic industrial settings, where floors must endure the rigours of heavy machinery and constant footfall without deteriorating.

Moreover, its sleek, customisable finish makes it a prime choice for contemporary retail and commercial spaces, providing a stylish foundation that enhances various interior designs. The low maintenance requirements of polished concrete further bolster its appeal, ensuring that floors remain pristine with minimal effort.

This blend of functional resilience and aesthetic versatility renders polished concrete an optimal flooring solution across a diverse array of applications.

High-traffic Industrial Settings

Polished concrete shines in high-traffic industrial settings, where its unparalleled durability and low maintenance make it an essential flooring choice. Capable of enduring the heavy burden of machinery, constant pedestrian movement, and accidental spills, polished concrete maintains its integrity and appearance over time.

This resilience positions it as the go-to option for factories, warehouses, and other industrial venues prioritising a long-lasting and efficient flooring solution.

Contemporary Retail and Commercial Spaces

In contemporary retail and commercial spaces, polished concrete offers a sleek and modern aesthetic that can be tailored to specific design preferences. Its ability to reflect light amplifies both natural and artificial illumination, creating a welcoming environment for customers.

The wide range of finishes and colours available enables a high degree of customisation, allowing businesses to craft a unique space that resonates with their brand. This combination of aesthetic flexibility and practical benefits renders polished concrete a popular choice among designers and business owners in the retail and commercial sectors.

What are the best use cases for epoxy flooring?

Epoxy flooring excels in environments that demand durable, easy-to-maintain, and aesthetically adaptable surfaces. Its superior chemical resistance and the option to integrate anti-slip additives render it perfect for any automotive garage floor where oil spills and heavy usage are common.

Additionally, the seamless and hygienic nature of epoxy flooring, combined with its resistance to bacteria and stains, makes it an excellent choice for healthcare facilities aiming to uphold sterile conditions.

The availability of a wide array of colours and patterns allows for extensive customisation, offering spaces not only functional benefits but also the opportunity to achieve a distinctive aesthetic. These qualities position epoxy flooring as a favoured solution in settings that prioritise durability, safety, and design versatility.

Automotive Garages with Chemical Exposure

Epoxy flooring stands out in automotive garages, where chemical exposure is a daily challenge. Its superior chemical resistance ensures longevity and ease of maintenance, even when subjected to oil, grease, and other automotive substances.

Incorporating anti-slip additives into the epoxy can significantly enhance safety, making it an essential feature in these high-activity areas. The combination of durability, low maintenance, and aesthetic appeal makes epoxy flooring an excellent choice for garages aiming to maintain a functional yet inviting workspace.

Healthcare Facilities Requiring Sterile Environments

For healthcare facilities that prioritises sterile environments, epoxy flooring provides an ideal solution. Its seamless and impermeable surface prevents the harbouring of dirt and bacteria, crucial for meeting the high standards of cleanliness required in medical settings. Epoxy’s robust resistance to stains and chemicals allows for the frequent use of disinfectants without compromising the floor’s integrity.

Furthermore, the customisable nature of epoxy flooring, with its wide range of colors and patterns, offers the opportunity to create a space that is not only functional but also aesthetically pleasing, contributing positively to the atmosphere for both patients and healthcare professionals.

How to decide between polished concrete and epoxy for your project?

Deciding between polished concrete and epoxy flooring for your project involves a careful assessment of several critical aspects. Initially, evaluate the specific needs of the environment, such as traffic levels, chemical exposure, and the requirement for sterile conditions. Polished concrete is typically preferred in settings that value durability and low maintenance, whereas epoxy flooring shines in areas needing chemical resistance and enhanced safety features like anti-slip surfaces.

Next, consider the aesthetic goals for the space. For those desiring a wide selection of colors and patterns, epoxy offers extensive customisation options. Conversely, polished concrete delivers a minimalist, industrial aesthetic with its distinctive glossy finish.

Finally, budget considerations are pivotal, with polished concrete generally presenting lower upfront costs, while epoxy may offer better long-term value due to its robustness and minimal upkeep requirements. By thoughtfully weighing these factors, you can make an informed choice that best suits the functional and aesthetic requirements of your project.

Assessing the Specific Needs of the Environment

Determining the right flooring—whether a polished concrete floor or epoxy flooring—begins with a thorough assessment of the environment’s specific needs. Considerations such as anticipated traffic, potential for chemical spills, and requirements for sterile conditions are crucial. Polished concrete is renowned for its durability and ease of upkeep, ideal for areas with high foot or vehicle traffic. In contrast, epoxy flooring’s exceptional chemical resistance and safety enhancements, including anti-slip properties, make it suited for specialised environments with stringent health and safety protocols.

Considering the Aesthetic Goals of the Space

The aesthetic objectives of your space significantly influence the choice of flooring. Epoxy flooring offers an extensive palette of colours and designs, providing limitless customisation possibilities to match any decor theme. Meanwhile, polished concrete brings a sleek, industrial look with its signature glossy finish, catering to spaces aiming for a contemporary, minimalist aesthetic. Understanding the visual impact and design flexibility of each option is key to achieving your desired ambiance.

Evaluating the Budget for Initial and Ongoing Costs

Budgetary considerations are critical, encompassing both initial investment and long-term maintenance expenses. While polished concrete typically presents lower upfront costs, it may necessitate additional treatments to meet specific aesthetic or functional requirements.

Conversely, epoxy flooring may involve a higher initial outlay due to comprehensive surface preparation and material costs but tends to offer reduced maintenance costs over its lifespan.

Carefully weighing these financial aspects against each flooring type’s durability and upkeep needs will guide you toward a financially sound decision for your project.